2023-04-07

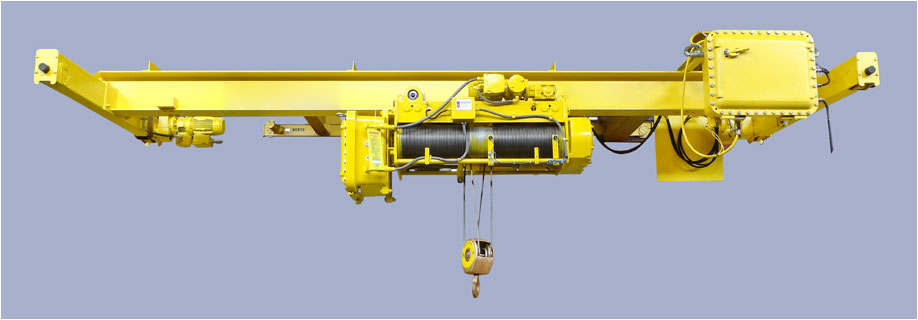

QB explosion-proof bridge crane is a kind of lifting equipment specially used for material handling in inflammable and explosive environment. It has the technical characteristics of preventing arc, spark and overheating from causing explosion. The explosion-proof bridge crane is mainly composed of explosion-proof electric hoist, explosion-proof metal structure, explosion-proof parts and explosion-proof transmission device. The cooperation and coordination between them is the key to ensure the safe and reliable operation of the crane. Explosion-proof bridge crane is an important equipment in chemical, petroleum, coal and other industries. It provides effective support and guarantee for production and logistics.

Explosion-proof bridge crane is divided into two categories according to the use of environment, according to the GB3836.1-2000 standard, according to the explosive gas environment is divided into class I and Class II electrical equipment; According to the provisions of GB12476.1-2000, electrical equipment for combustible dust environment is only one class, and the corresponding explosion-proof bridge crane is classified as follows:

Class I: Crane for coal mines

Class II: Cranes for explosive gas environments other than coal mines.

The standard parameters of QB explosion-proof bridge crane are:

Load capacity: 3-50 tons

Span: 10.5-31.5 meters

Lifting height: ≤16

Lifting speed: 2-8 m/min

Car running speed: ≤ 25m/min

Crane running speed: ≤ 25m/min

Job level: A3, A4

The explosion-proof principle of QB type bridge crane is to take corresponding measures to control spark generation. That is, the use of appropriate explosion-proof techniques to control and eliminate electrical and mechanical sparks so that they cannot ignite flammable gas mixtures and environmental areas. Flammable dust and mechanical sparks Special sparkless materials are used to control the content of magnesium and titanium in the light alloy shell in the parts prone to dangerous sparks, so as to avoid collision and friction between relative moving mechanical parts, so as to achieve explosion-proof.

Some safety measures to be taken when using an explosion-proof bridge crane include:

1. Provide appropriate training for all operators and maintenance personnel.

2. Periodically check and maintain all components.

3. Use proper personal protective equipment (PPE), such as hard hats, safety glasses, and gloves.

4. Properly ground all electrical equipment.

5. Proper ventilation of work area to prevent accumulation of flammable gas or steam.

6. Correct storage and handling of all flammable materials.

Copyright @ Guangdong Yongtong Crane Machinery Co., Ltd. 粵ICP備2022051937號